Production of the Meneely bellfoundry,

Troy, New York, USA (1871-1951)

The Meneely (Troy) bellfoundry is the only one of the American bellfoundries for which sufficient information is readily available to make a detailed analysis of its production of bells over the history of the company.

Here you will find some analysis of that production, as well as information about the ledger on which that analysis is based.

This page contains

- a brief analysis of the ledger data,

- some caveats regarding the analysis,

- a list of some notable bells,

- the identification of the transcription from the ledger,

- a description of the ledger.

Analysis of the ledger

The figures and graphs presented here are not precisely accurate, for reasons which are given in the caveats that are stated in the next section of this page. Nevertheless, the broad-brush picture is undoubtedly correct.

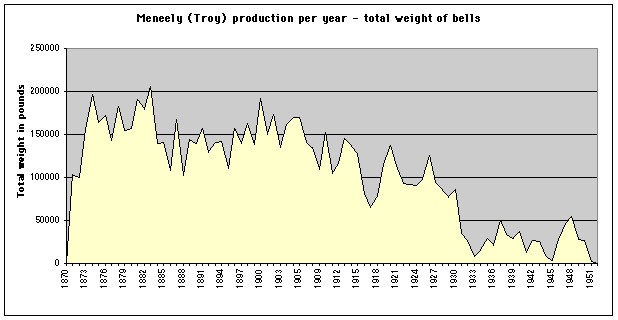

Of the 8,668,234 pounds of bell metal listed in the ledger, 8,615,700 pounds can be attributed to specific years, producing the following graph of total weight of bells shipped per year:

The most productive year from this viewpoint was 1883, when more than 205,000 lbs of bell metal were shipped.

The impact of World War I is clearly visible as a large dip in the graph centered around 1917.

The impact of the Great Depression (in the early 1930s) was obviously catastrophic, as was World War II.

The Korean War was the last straw, putting an end to this business as it did to the few other American bellfoundries that had survived to that time.

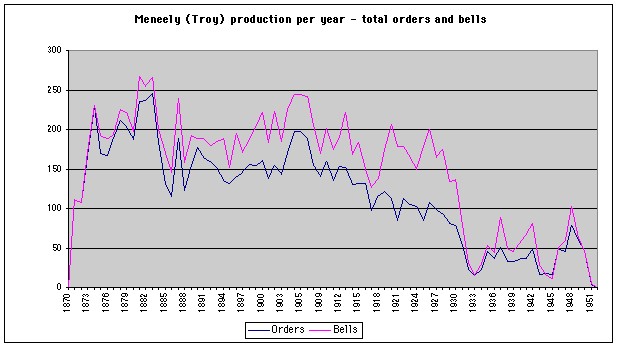

Of the 12,406 bells listed, 12,328 bells can be attributed to specific years, producing the part of the following graph which shows the number of bells shipped per year (violet line):

The most productive year from this viewpoint was again 1883, when 266 bells were shipped, and 245 orders were filled.

Of at least 9662 listed orders for new bells, 9599 can be attributed to specific years, producing the other part of the graph above (dark blue line).

The general shapes of both parts of this figure follow closely the shape of the graph for production tonnage (above).

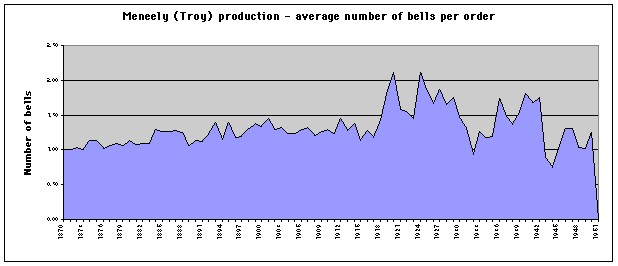

Dividing the number of bells shipped each year by the number of orders handled that year produces the following graph of average number of bells per order:

The graph begins at 1.0, because initially the foundry was producing only single bells.

The average rose as the foundry began to produce occasional peals, chimes, etc.

In later years, the average is less than 1.0 when the number of orders was small and some sales were of recycled bells.

Such orders were transcribed with the number "0" since they were not for newly cast bells.

It is undoubtedly significant that the shape of this graph is much different from the shapes of the preceding graphs.

The foundry was producing more bells per order while producing less bells for fewer orders.

Over the lifetime of the foundry, the average number of bells per order was 1.25.

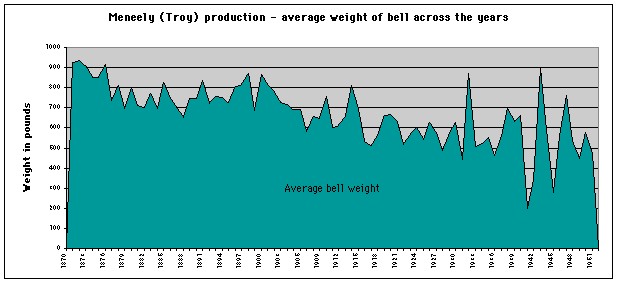

The average weight of bell shipped varied as follows:

The general decline in that average weight can be attributed in part to a fairly steady increase in the number of bells made for places other than church towers - bridges, plantations, small ships, etc.

In addition, bells shipped overseas to various mission churches or schools were generally small in comparison to those for churches or schools "at home."

Finally, the treble bells of peals and chimes are significantly smaller than the accompanying bass bells.

A related but distinctly different view of the Meneely (Troy) production history can be found in our summary of North American chimes.

Other analyses of the Meneely (Troy) ledger data probably could be done. If there's one you'd like to see, use the email link at the bottom of this page to suggest it.

Caveats regarding the analysis above

There are several difficulties with making any statistical analysis of the ledger.

Most obviously, some entries are incomplete. There are 9662 entries which report the number of bells in a shipment (ranging from 1 to 32), plus 79 which report "0" bells. (The latter sometimes represent the sale of second-hand bells, either Meneely's own or someone else's. Sometimes they represent other work, such as parts or electrification.) That gives a total of 9741 entries. But only 9625 entries report total shipment weight, and only 9503 report weight of the largest bell in the shipment. Some are also missing the date; no count of these is yet available.

Furthermore, in many cases the weights of individual bells are pattern weights, not exact weights. While it might be assumed that Meneely would have weighed every bell produced (since billing may well have been on a per-pound net weight basis), it is clear that those explicit weights did not always get recorded in the ledger. So it would be inaccurate to claim a precision in these figures that the underlying data just do not support.

On the other hand, the total shipping weight recorded for chimes and for peals of medium to large bells seems in every instance to be an actual as-weighed value, rather than a sum of pattern weights for the individual bells making up the shipment. This fact undoubtedly operates to reduce the possible uncertainty in sums calculated from the recorded weights.

SPECIAL NOTE (Sept.2016): It has recently been discovered that a few lines were accidentally omitted from the ledger transcription on which the analysis was based, and a few others were misinterpreted or accidentally combined. Proofreading and revision of the edited transcription are in progress, but will take some time to complete. Meanwhile, although specific numbers presented herein are undoubtedly slightly inaccurate, their relative magnitudes should be reasonably accurate, as will also the shapes of the graphs above.

Notable bells

Great bells: The foundry made two great bells of 13,000 pounds - a weight which is obviously symbolic of the original 13 American colonies.

- 1876 - U.S. Centennial Bell

- 1893 - Columbia Liberty Bell

- In 1912, a single bell of 7515# was shipped to First Church of Christ, Scientist, San Diego, California. Four years later, the church sold it back to the foundry, which presumably melted it down, as there is no record of its resale.

- In 1896, a 10-bell chime with a tenor of 7283# was made for the Minneapolis Court House and City Hall; this was also the heaviest single shipment of bells recorded in the ledger. This chime was later enlarged by the same bellfoundry.

- In 1941, a 32-bell electric-action carillon with a tenor of 7000# was made for Dayton, Ohio. This is the only carillon-sized instrument ever made by the Meneely Bell Company, and was probably the heaviest single shipment ever made from the foundry. (In fact, it was dispatched in two shipments; unfortunately the total weights were not recorded.) This instrument was later replaced by a traditional carillon from a different manufacturer.

- In 1925, a 20-bell chime was made for Grace Episcopal Church in New York City. With a total weight of 26648#, this was the second-heaviest single shipment ever made from the foundry, and the largest chime ever made there.

- In 1928, a 15-bell chime was made for Dartmouth College, Hanover, New Hampshire. With a total weight of 21351#, this was the third-heaviest single shipment ever made from the foundry, and it is tied for the second-largest chime ever made there. (The foundry made one other 15-bell chime, but it was distinctly lighter in weight.)

- Out of 139 shipments of four bells, 116 can certainly or probably be identified as clock-chimes.

All but one of them have the musical configuration for the Cambridge (Westminster) quarter-chime tunes: "mi,re,do,Sol," with the hour strike on the heaviest quarter-bell, and many of them were explictly identified in the ledger as a "Westminster Peal."

The sole exception is one which is known from other evidence to play a unique quarter-chime tune.

Five of these clock-chimes have bass bells that rank among the eight heaviest non-great bells from this foundry.

All were hung on commercial buildings, as follows (in order by weight):

- 7430# bass, 14665# total, Aug.1925

St.Mary of the Lake, Mundelein, Illinois

(now The University of St.Mary of the Lake, the seminary of the Roman Catholic Archdiocese of Chicago) - 7201# bass, 13851# total, Westminster Peal, Apr.1924

310 South Michigan Avenue, Chicago, Illinois, USA

S. W. Straus & Co.

425 feet above ground - 7201# bass, 12733# total, unique quarter-strike tune, Dec.1926

Roanoke Building, Chicago, Illinois, USA

450 feet above ground - 7093# bass, 13481# total, "Cambridge Quarters", Jan.1909

Metropolitan Life Ins. Co., New York City

650 feet above ground; audible up to 28 miles away - 7075# bass, 13646# total, Oct.1924

Roydhouse-Arey Co., Philadelphia, Pennsylvania, USA

- 7430# bass, 14665# total, Aug.1925

- Out of 13 shipments of five bells, four can certainly or probably be identified as clock-chimes, with the musical configuration for the Cambridge (Westminster) quarter-chime tunes, and having the hour strike one whole tone deeper in pitch than the heaviest quarter-bell. Although a 5-bell clock-chime might be considered more musically satisfying than the 4-bell version, none of these four is particularly noteworthy in terms of weight.

- There were 42 orders for a total of 44 bells to go with fire alarm systems installed by the Gamewell Fire Alarm Telegraph Company, with weights ranging from 150 to 2000 pounds.

- There were 75 orders for alarm bells (all single) not associated with Gamewell, with weights ranging from 30 to 4000 pounds.

- There were 142 orders from fire companies, city fire departments, etc., for single bells ranging in weight from 20 to 5200 pounds.

- Out of 8 shipments of six bells, two were for expanding 4-bell clock-chimes into 10-bell musical chimes. The remainder were assortments of small bells, some less than 20# each, apparently for use on multiple ships, factories or plantations.

- There were only two shipments of seven bells, both assortments of small bells. One was for Lutheran mission churches in Africa, while the other was for Fifth Avenue traffic bells in New York City.

- There were at least 800 orders from or for schools, ranging in size from 20 to 2000 pounds.

The details listed above barely scratch the surface of what might be discovered with deeper analysis of the ledger data.

Identification of the transcription

Besides the thousands of their bells scattered around the world, one particularly interesting artifact survived from the operation of the Meneely bellfoundry of Troy, New York. That was a ledger of the bells which the foundry produced. It might also have served as an index into company records of prior production. The original transcription of that ledger can be found at the Website of the Hudson Mohawk Industrial Gateway, as a very large Excel spreadsheet. An edited version of that spreadsheet is in the possession of the author of the page which you are now reading, and was used to prepare the analyses which are presented above. That version is in the form of an Excel workbook, which enables searching and analysis of the data contained therein. The numbers and graphs presented above represent a very high-level and superficial analysis, but nevertheless give a general picture of the ups and downs of the foundry's operations over the course of its eight decades of existence.

From the title sheet of the edited transcription workbook:

Being the record of production of bronze bells by

Meneely & Kimberly, Troy, N.Y., USA, 1869-1879

Meneely Bell Company, Troy, N.Y., USA, 1879-1951

with annotations by

Kehn Bell Service, Troy, N.Y., USA, 1951-1990

transcribed by

Jess Brodnax, Hudson Mohawk Industrial Gateway, Troy, New York, USA

edited by

Carl Scott Zimmerman, Campanologist, St.Louis, Missouri, USA

Description of the ledger

From the title sheet of the transcription workbook:The ledger which is the source of this document, and from which the data in this document was transcribed, records the production of more than 12500 bells, over most of the span of existence of this bell foundry. (The earliest date given is actually in 1871.) The casting of these bells consumed more than 4300 short tons of bronze (approximately 80% copper and 20% tin).

While most of the bells (more than 9000) were shipped singly, the foundry did produce one electric-action carillon, more than 150 chimes of 8 to 20 bells, many clock-chimes of 4 or 5 bells, and numerous peals of 2 to 5 bells. When miscellaneous groups of bells are included, there were more than 730 multi-bell shipments.

The heaviest chimes and peals had a bass bell of about 2.5 tons, and these were probably the largest bells this foundry ever hung for swinging. The heaviest clock-chimes and the carillon had a bass bell of about 3.5 tons, but these would have been hung "dead". Two huge bells of about 13000 pounds were made for special purposes; otherwise the largest single bell made was about 7500 pounds. The smallest bells listed are ship bells of about 10 pounds.

The great majority of bells were shipped to churches; the rest went to schools, businesses, municipalities and private estates. Identified non-religious applications are clock bells, school bells, fire bells, bridge bells, traffic bells and ship bells. Quite possibly some were used for other purposes that were not recorded here.

Physically, that ledger is a large leatherbound ledger of about 300 leaves, which are printed on both sides to yield 600 pages. As purchased, this was a blank book of about 60 un-numbered lines per page, with vertical ruling into five unlabeled columns, and with sequential page numbers pre-printed in the upper outer corner of each page. The original compiler of the ledger allocated the pages in roughly alphabetic order by American state names interspersed with foreign country or continent names. (For example, the page for Alaska is followed by a page for Australia and then two pages for Africa; next comes the page for Arizona.)

The number of pages allocated for each geographic unit varies. For example, while Asia has only one page (following Arkansas and preceding a page for foreign countries beginning with B), the state of New York has 168 pages which are sub-allocated on the basis of the first letter of the city name. The larger multi-page states have the cities in alphabetic order by the first letter, while single pages and smaller multi-page states list the cities in chronological order (or no order at all).

The column layout is well suited to reporting shipments of single bells, but not so well suited for reporting multi-bell shipments. Several different expedients were adopted, the commonest of which was to include a "chime" or "peal" description with the institution name in the Location column. Such a description usually included the weights of the individual bells, with their total weight being entered in the Weight column. However, when several relatively small bells were being shipped to a buyer who would presumably disperse them to several locations, the individual weights were often listed in the Weight field, with no total reported.

Use of this ledger appears to have begun shortly before 1912. According to the late Ed Kehn, former plant engineer for the foundry and a principal of Kehn Bell Service, the ledger was started by one of the three sons of Clinton H. Meneely, who had set up the foundry in 1869 in partnership with Mr. Kimberly. He determined the ledger column usage according to the types of information which he wanted to record about the weight, destination and date of the bells. He probably determined the initial page assignments based on the geographic distribution of bell sales in preceding years. He must have used existing foundry files to obtain information about prior shipments, because all entries dated up to about 1912 are written in a uniform style with the same color of ink and same type of pen nib, and on any given page these entries tend to be written in chronological order. After 1912, there is increasing variation in penmanship, ink, etc.

As use of the ledger continued through subsequent years, there arose situations where new entries did not conveniently fit into the planned layout. Thus where the limited alphabetic order is used, non-adjacent later entries for the same institution (or simply the same city) are sometimes connected to earlier ones by the use of "above" and "below" tags. Also, there were numerous instances where a previously-supplied bell was replaced (because of cracking, destruction by fire, etc.). Often this was handled by writing the weight and date of the new bell above the corresponding figures of the original entry after the latter were crossed out.

It appears that shortly after World War II, some effort was made to determine what previously-shipped bells still existed. There are annotations in a different ink and style about "no such post office", or with alternate versions of town or institution names. Other annotations obviously reflect news that was received by the foundry offices, or actions such as buying back a bell that was no longer needed. A few of these annotations are dated; many, unfortunately, are both undated and cryptic.

At the closure of the foundry (if not before), the ledger passed into the hands of the Kehn Bell Service, which performed maintenance work on all kinds of tower bell installations. KBS made additional annotations of various kinds in the ledger, some reflecting work which they performed (e.g., electrifications) and some recording the current status of previous installations.

Return to the Meneely/Troy foundry index page.

[TowerBells Home Page] [Site data top page] [Credits and Disclaimers] [Feedback]

This page was created 2009/10/16-17, and last revised on 2021/02/24.

Please send comments or questions about this page to csz_stl@swbell.net.