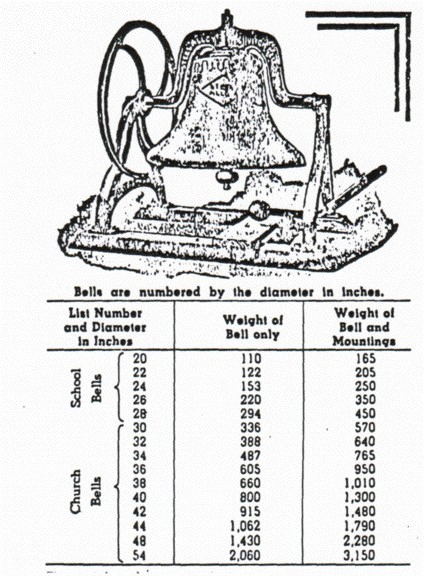

Bell weight tables

Major American bellfoundries of the late 19th and early 20th centures commonly included tables of bell weights in the catalogs of their products. One reason for doing this was to tell prospective purchasers how much space would be required in the belfry for a swinging bell. The clear space required for a rope wheel was typically larger than the longer dimension of the floor space required for the factory-supplied timber base upon which the side supports and tolling hammer were mounted. Some foundries also included the price of the mountings (timber frame, cast iron side supports and yoke), as these prices did not vary nearly as much as the prices of the bells themselves, which were heavily dependent upon fluctuations in the prices of copper and tin - the components of bell metal.

Contents of this page:

Tables of weights for bronze bells

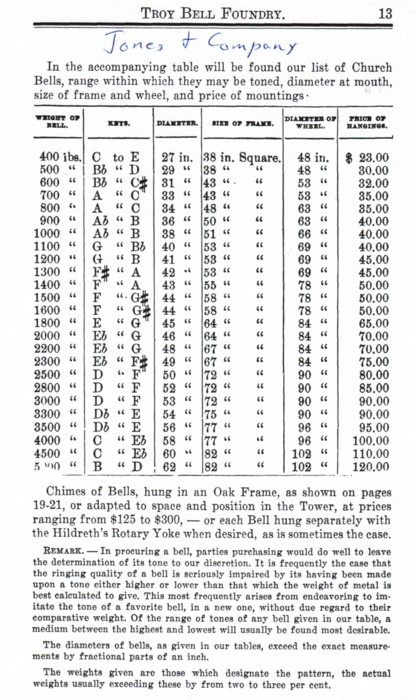

The Jones & Company Troy Bell Foundry, Troy, New YorkSince the note or pitch of a bell is determined by its inside diameter at the strike point, and this table shows a wide variety of notes for a given weight (a range of a minor or major third), it is evident that the Jones foundry was being surprisingly honest about their inability to produce bells with a consistent profile.

McShane Bell Foundry, Baltimore, Maryland

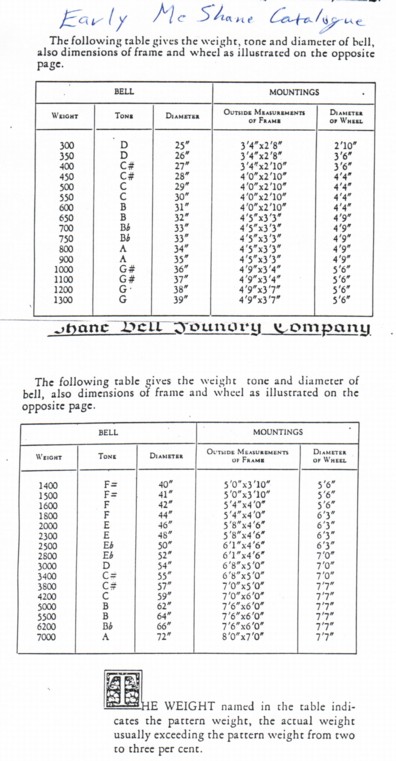

Weight, Tone (pitch) and Diameter from an early catalog

This foundry apparently had better control of its bell profiles than Jones did, but the resulting tones were not as accurate as this table seems to imply. Single bells from this and other American foundries could be a quarter-tone off the claimed note in either direction. Apparently McShane also claimed to be able to produce heavier (and deeper-toned) bells; but it is not known what their heaviest bell actually was.

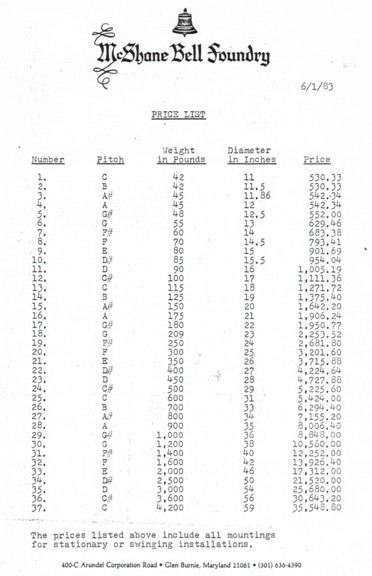

Weights and prices (bell and fittings) from a 1983 letter

This table shows a pitch range of three octaves, with a single pattern weight for each pitch.

Meneely Bell Company, Troy, New York

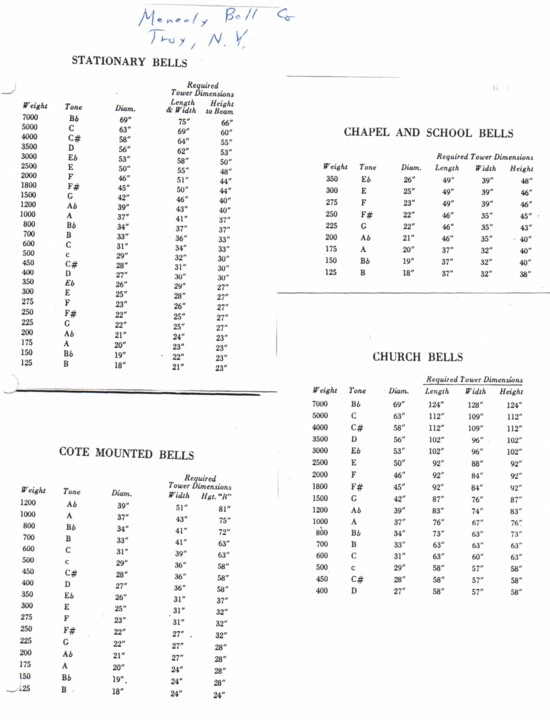

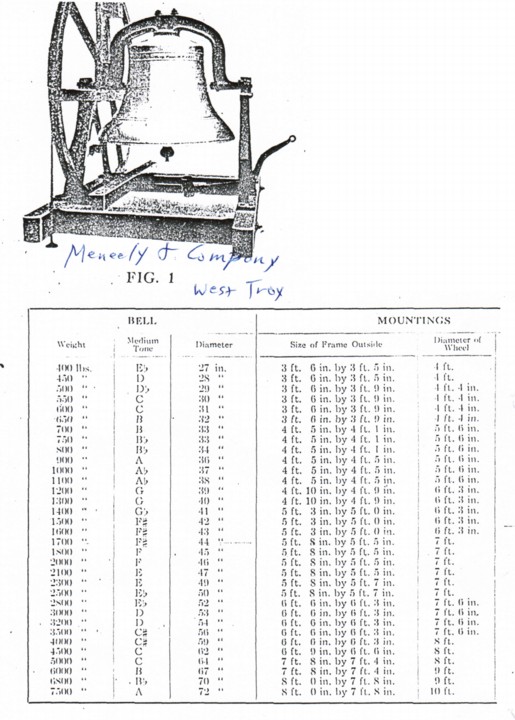

Separate tables were provided to account for the different ways in which bells could be installed. Stationary bells include clock bells and fire alarm bells, both affixed to an existing horizontal beam. Bells hung in a bell cote have unlimited space in one direction, and their bearings are embedded in the side walls of the cote. Church, chapel and school bells all swing, in frames that stand on a factory-supplied base that must be supported by an existing floor or similar structure.

This table accurately reflects the foundry's capability to make large bells, as some are known in the 7000# range.

Meneely & Company, West Troy (later Watervliet), New York

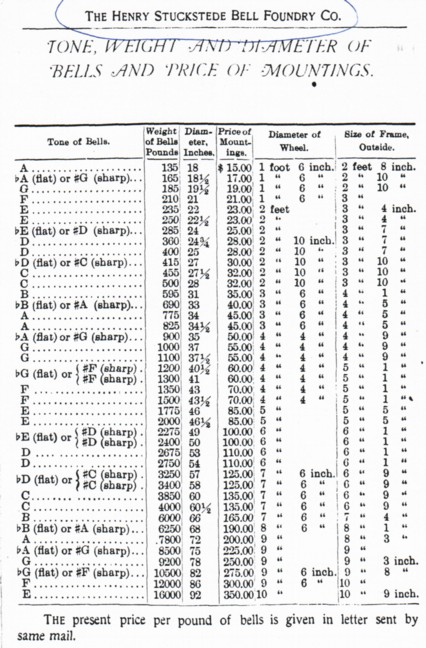

The Henry Stuckstede Bell Foundry Company, Saint Louis, Missouri

This was the final stage of the first Stuckstede bellfoundry.

The very heavy capability suggested by this table was probably only wishful thinking on the part of a bellfounder who was more salesman than craftsman; the largest known bell from this foundry is about 6000 pounds.

The drawing on this page is based on the style of decoration used by this foundry before Henry Stuckstede took control of it.

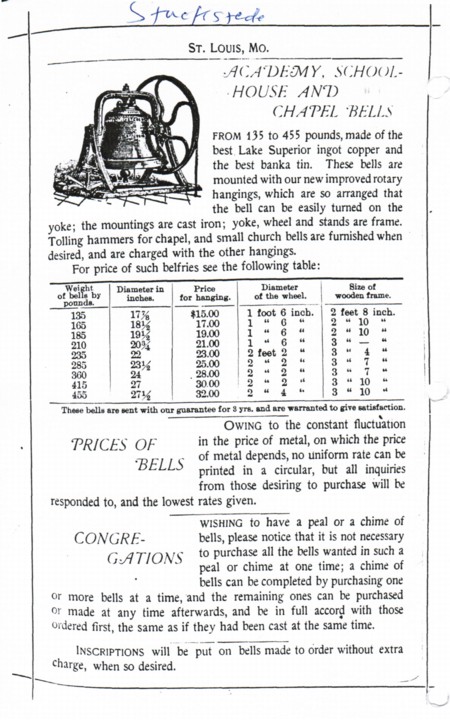

Stuckstede & Bro., Saint Louis, Missouri

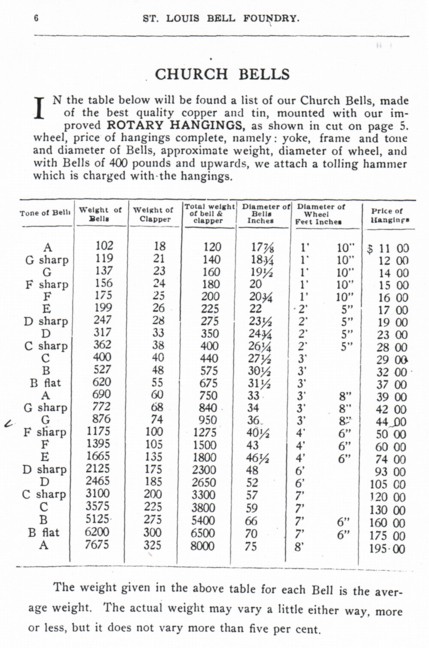

This was the second Stuckstede bell foundry; it was operated by two nephews of Henry Stuckstede, and competed with his foundry for more than 40 years. The name Saint Louis Bell Foundry was used in advertising material such as this, but never appears on any of their bells.

The largest bell by them found to date is a D# of about 2200 pounds.

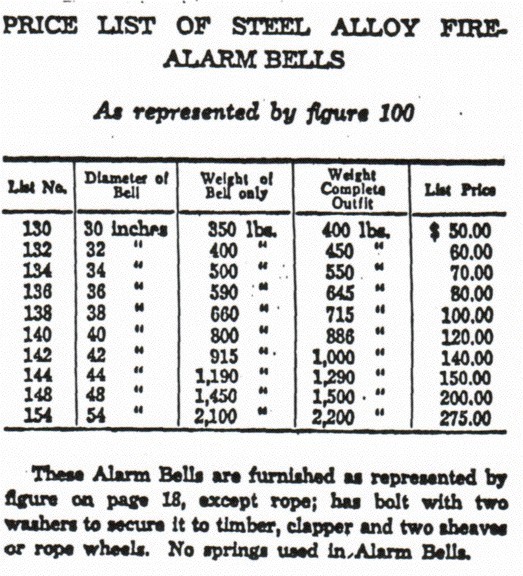

Tables of weights for steel bells

Makers of these bells did not give notes, possibly because the notes of these bells are rather indeterminate.The C.S.Bell Company, Hillsboro, Ohio

[TowerBells Home Page] [Site data top page] [Credits and Disclaimers] [Feedback]

This page was created 2016/12/31 and last revised 2018/10/30.

Please send comments or questions about this page to csz_stl@swbell.net.